China Fiberglass bracket Manufacturer, Supplier, Factory

We'll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for Fiberglass bracket,Solar panel composite frame,Fiberglass solar panel bracket,Fiberglass photovoltaic bracket,Photovoltaic fiberglass bracket, We warmly welcome friends from all walks of life to cooperate with us.

Fiberglass bracket, Our mission is "Provide Merchandise with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Hot Products

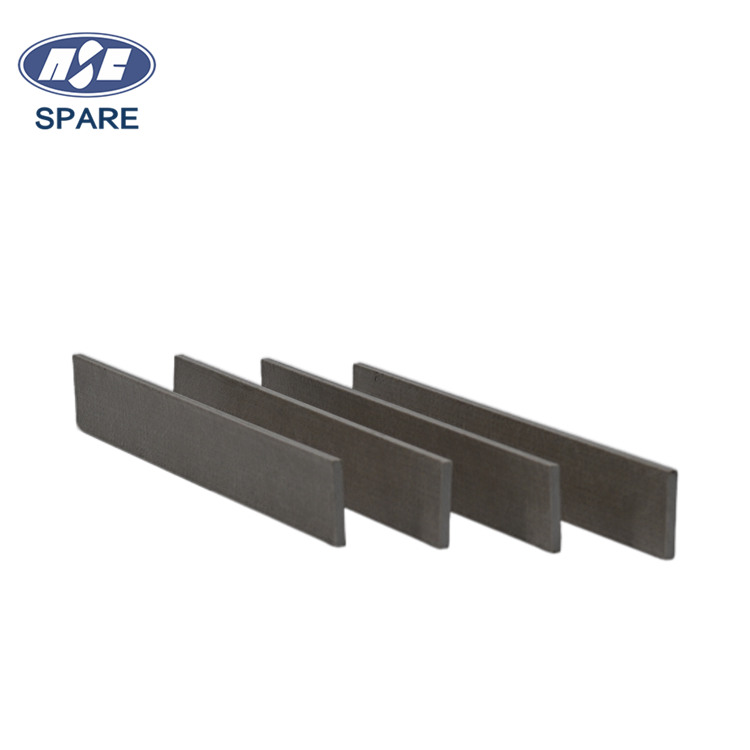

FRP Pultruded Flat Plate

FRP pultruded flat plate is a flat plate material made of fiberglass and resin composite materials. It has the characteristics of light weight, high strength, corrosion resistance, insulation, etc., so it is widely used in many fields.FRP Handrail

Ideal for durability, safety and environmental protection

Our Fiberglass (Fibre Reinforced Plastic) handrails are well-designed, durable and reliable marine engineering solutions. Using advanced materials and processes, our FRP handrails offer outstanding performance and a variety of benefits.Fiberglass T Profiles

Fiberglass T Profiles are crafted using premium Fiber Reinforced Polymer, combining strength, durability, and a lightweight design to meet the diverse needs of modern engineering and construction. These profiles are designed for versatility, making them ideal for a variety of structural and aesthetic applications.FRP Rods

FRP Rods are round material made of Fibre Glass Reinforced Plastic (FRP). It has the advantages of light weight, high strength and corrosion resistance, and is suitable for various applications, such as construction, power, chemical, etc. FRP Rod is widely used as a replacement for metal and traditional materials due to its excellent performance.FRP Skirting Board

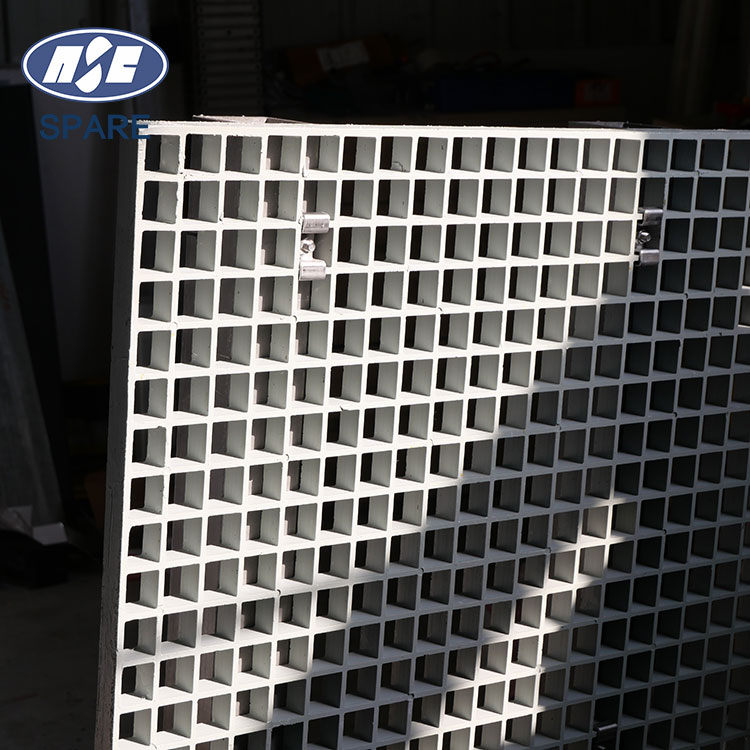

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Skirting Board is customized product.FRP Pallets

Our new FRP Pallets provide an innovative and sustainable alternative to traditional wooden pallets. Engineered from high-quality fiberglass reinforced polymer (FRP), these pallets are lightweight, durable, and resistant to corrosion and chemicals. Perfect for diverse industries, FRP pallets enhance efficiency and hygiene in your material handling operations.