HGFRP Composites See Rising Demand in Infrastructure and Green Energy Applications

In recent years, High Glass Fiber Reinforced Polymer (HGFRP) has gained significant traction across various industries, driven by growing demands for lightweight, durable, and corrosion-resistant materials. As a next-generation composite material, HGFRP offers higher strength and stiffness than conventional FRP, thanks to its increased glass fiber content and advanced resin systems.

According to recent market data, the global HGFRP market is expected to grow at a CAGR of over 6% from 2025 to 2030, with key growth sectors including construction, transportation, renewable energy, and marine engineering. The shift toward sustainable materials and infrastructure resilience is accelerating adoption in areas such as:

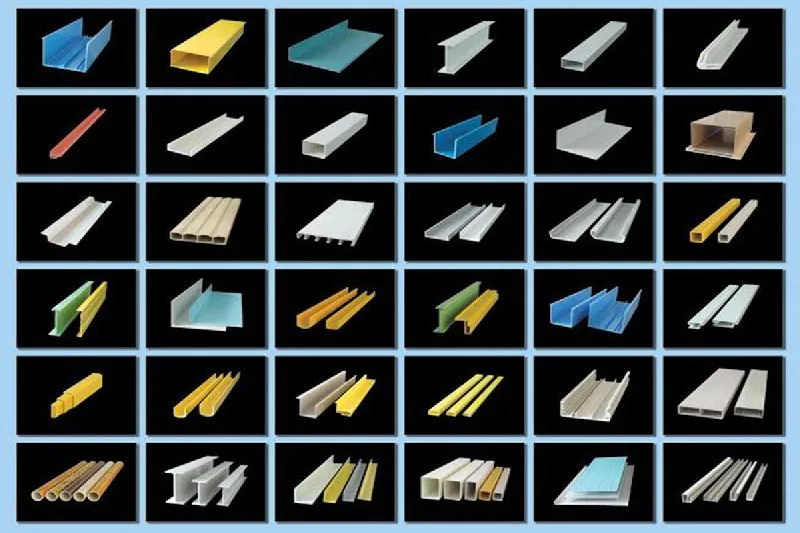

● Bridge Decks and Structural Profiles: HGFRP is being increasingly used in pedestrian and vehicular bridges for its excellent load-bearing capacity and resistance to environmental degradation.

● Wind Turbine Components: The material’s high strength-to-weight ratio makes it ideal for manufacturing large wind turbine blades and support structures.

● Electrical and Utility Applications: With superior insulation and fire resistance, HGFRP products are replacing metal in power grid components, cable trays, and substations.

Industry leaders have also noted that the recyclability and low maintenance cost of HGFRP make it an attractive choice for long-term infrastructure investments. Ongoing R&D efforts are focusing on optimizing the pultrusion process, enhancing fiber-matrix bonding, and developing bio-based resins to further reduce environmental impact.

As the world shifts toward greener construction and smarter materials, HGFRP stands out as a material of the future — strong, adaptable, and aligned with sustainable development goals.