China FRP Cover Manufacturer, Supplier, Factory

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for FRP Cover,Fiberglass Cover Plate,Fiberglass Cover,GFRP Covers,GRP Covers, We adhere towards the tenet of "Services of Standardization, to fulfill Customers' Demands".

FRP Cover, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which might be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Hot Products

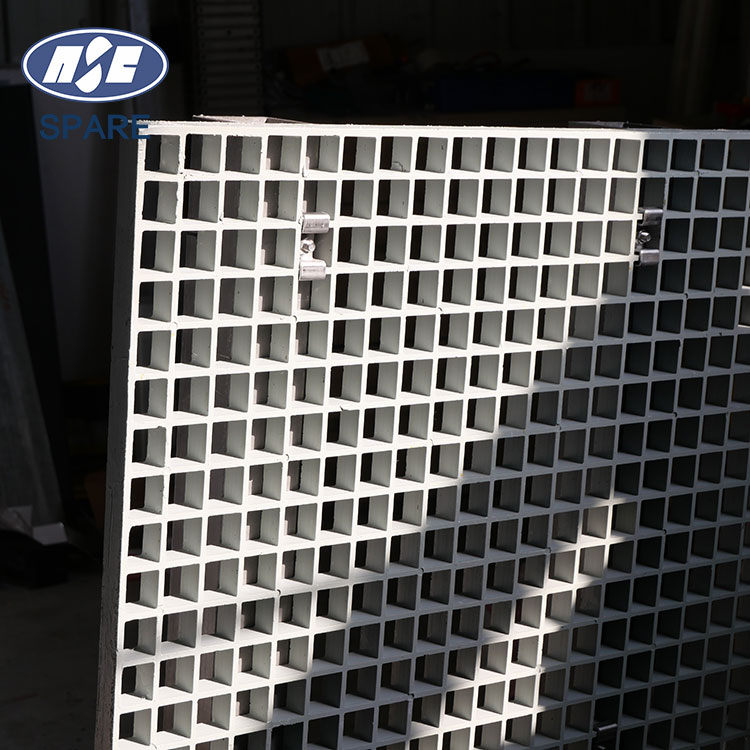

Molded Fiberglass Grating

Molded fiberglass grating is a grating product made of glass fiber reinforced plastic (FRP) through a molding process.Vehicle Composite Profiles

Our FRP composites are at the forefront of enhancing the structural components of new energy vehicles. Our Vehicle Composite Profiles include key elements such as Column Reinforcements, Battery Pack Spacer Beams, Crossbeams, Roof Beam Reinforcements, Door Beams, and Longitudinal Beams. Designed for the next generation of vehicles, these profiles offer unmatched strength and durability, crucial for the rigorous demands of new energy vehicle architecture.FRP Optical Cable Core Fiberglass Rod

The FRP Optical Cable Core Fiberglass Rod is a high-strength, lightweight composite material specifically designed for use within optical cable structures. It delivers excellent tensile strength, corrosion resistance, and durability, making it suitable for challenging environments and ensuring the longevity and stability of optical cables.FRP Wood Grain Profile

FRP Wood Grain Profiles combine fiberglass-reinforced plastic (FRP) with a wood-like finish, offering the look of natural wood with the durability and low maintenance of FRP. Ideal for both residential and commercial use, they mimic the textures and colors of real wood, making them perfect for exterior cladding, furniture, and decorative trim.GFRP Handle Tube

Pultruded GFRP round tubes are designed for tool handle applications requiring high strength, light weight, and corrosion resistance. Made from continuous glass fiber and thermosetting resin, these tubes offer excellent durability and electrical insulation, ideal for gardening, cleaning, and industrial hand tools.FRP Ladder

Durable and Lightweight FRP Ladder – Corrosion-Resistant and Electrically Insulated

Made of high-strength fiberglass reinforced plastic (FRP), this A-frame ladder is built for safety and durability. Ideal for electrical work, maintenance, and industrial applications where insulation and corrosion resistance are critical.