- Custom Pultrusion Shapes

- FRP Standard Profile

- Vehicle Composite Profiles

- FRP Bridge Components

- FRP Ladder Rail Profiles

- FRP Tool Handles

- FRP Epoxy Pultruded Profiles

- Fiber-Reinforced Connectors

- FRP Covers

- Composite Cooling Tower

- FRP Decking Solutions

- FRP Grating

- Fiberglass Handrail and Fencing

- Fiberglass Windows and Doors Profiles

- Structural Reinforcements and Profiles

- Composite Frames for Solar Panels

- FRP Cable Tray

Vehicle Composite Profiles

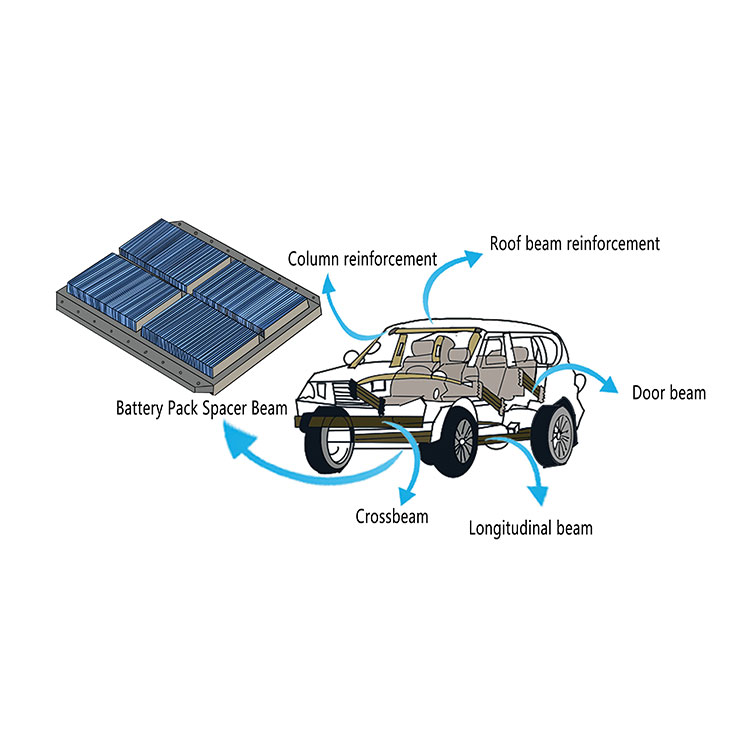

Our FRP composites are at the forefront of enhancing the structural components of new energy vehicles. Our Vehicle Composite Profiles include key elements such as Column Reinforcements, Battery Pack Spacer Beams, Crossbeams, Roof Beam Reinforcements, Door Beams, and Longitudinal Beams. Designed for the next generation of vehicles, these profiles offer unmatched strength and durability, crucial for the rigorous demands of new energy vehicle architecture.

Send Inquiry

Vehicle Composite Profiles

Our Vehicle Composite Profiles are engineered to meet the diverse needs of new energy vehicles, enhancing safety, efficiency, and performance through specialized components:

Column Reinforcement:

These profiles strengthen the vehicle's pillar sections, crucial for protecting occupants and maintaining structural integrity in case of a collision.

Battery Pack Spacer Beam:

Specifically designed to improve battery safety and efficiency, this component provides essential spacing between battery cells to ensure optimal thermal management and stability. Its role is vital in preventing cell misalignment and mitigating the risk of thermal runaway, thereby enhancing the overall safety and performance of the battery system.

Crossbeam:

Serving as a critical support structure, the crossbeam connects opposite sides of the vehicle, adding rigidity and helping to distribute loads evenly across the frame during impact.

Roof Beam Reinforcement: These beams are integral to reinforcing the roof structure, ensuring it remains intact and provides additional safety during rollovers or heavy impacts.

Door Beam:

Installed within the door frame, these beams help protect passengers by absorbing and deflecting side-impact forces, thus preventing intrusions into the cabin.

Longitudinal Beam:

Running lengthwise along the vehicle, these beams provide a backbone for the vehicle, contributing to better load distribution and structural alignment which is essential for vehicle dynamics and stability.

Understanding the FRP Pultrusion Process

We are manufactures, engineers, designers and fabricators.

Benefits of FRP

Framework stability

Superior corrosion resistance

lightweight

Easy to install

High Strength

customisable

Durability

Non-Conductive

Non-Magnetic

Thermal Stability

Low Maintenance Costs

Low Thermal Conductivity

Qualification Certificate