China Quadrangular Tube Manufacturer, Supplier, Factory

With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for Quadrangular Tube,Omega Profile,FRP Stair Tread Covers,Pultrusion Process,Resin, We warmly welcome good friends from all walks of life to cooperate with us.

Quadrangular Tube, So far our goods have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality goods and excellent service.

Hot Products

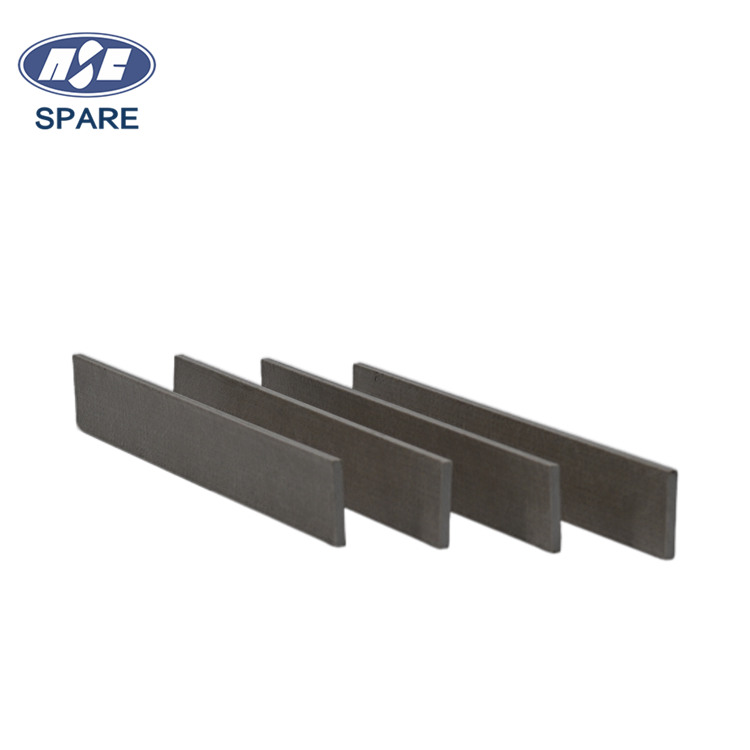

FRP Pultruded Flat Plate

FRP pultruded flat plate is a flat plate material made of fiberglass and resin composite materials. It has the characteristics of light weight, high strength, corrosion resistance, insulation, etc., so it is widely used in many fields.Trough Type Fiberglass Bridge

The trough type fiberglass bridge is a bridge product made of glass fiber reinforced plastic (GRP). It has the following features and advantages:GFRP Cable Tray

The ladder type GFRP cable tray is a structural cable support system made from glass fiber reinforced polymer (GFRP), featuring a stepped or trapezoidal design. It is ideal for routing cables across height differences or along slopes.Molded Fiberglass Grating

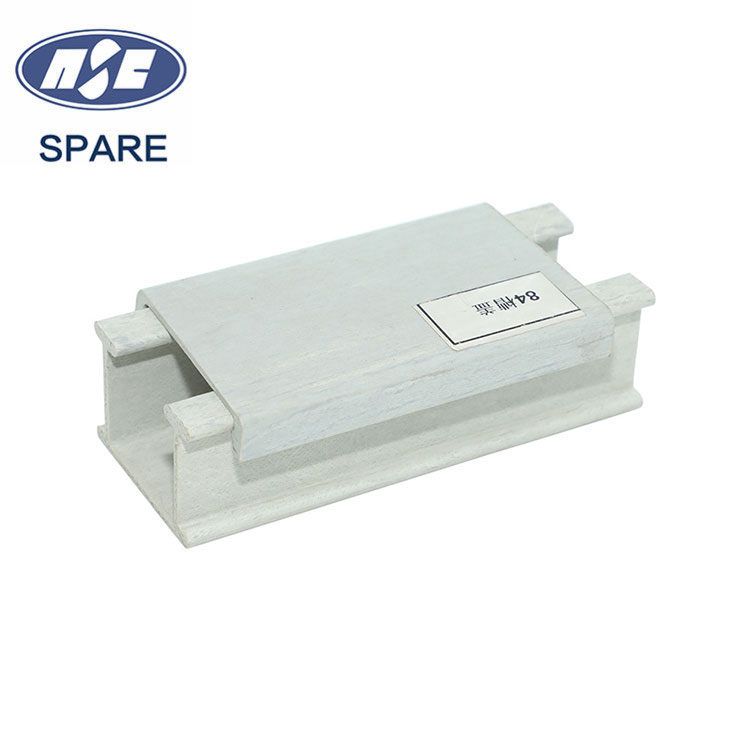

Molded fiberglass grating is a grating product made of glass fiber reinforced plastic (FRP) through a molding process.FRP Groove Box

All display products are customized products, specifications, shapes can be customized according to your needs, if you interested in any product details, we look forward to your inquiry, which will encourage us to develop new products. FRP Groove Box is customized product.FRP Insulated Sandwich Panel

FRP insulation sandwich panel is made of high-strength FRP panel and high-efficiency heat preservation core material composite, both structure and heat preservation function. The panel is corrosion-resistant and ageing-resistant, and the core material is made of high-quality thermal insulation material with excellent thermal insulation performance, which can effectively reduce energy consumption.

The light weight and high strength of the product can reduce the building load, and the construction is convenient and efficient, shortening the construction period. The fireproof grade is up to the standard, adapting to a variety of climatic environments, with a long service life. Green environmental protection, no harmful substances release, widely used in industrial plants, warehouses, cold storage and other buildings of the wall and roof, is a set of energy saving, safety, durability as one of the new building materials.