Equipment is the foundation, craftsmanship is the soul - a tribute to the "Spare people"

2025-08-06

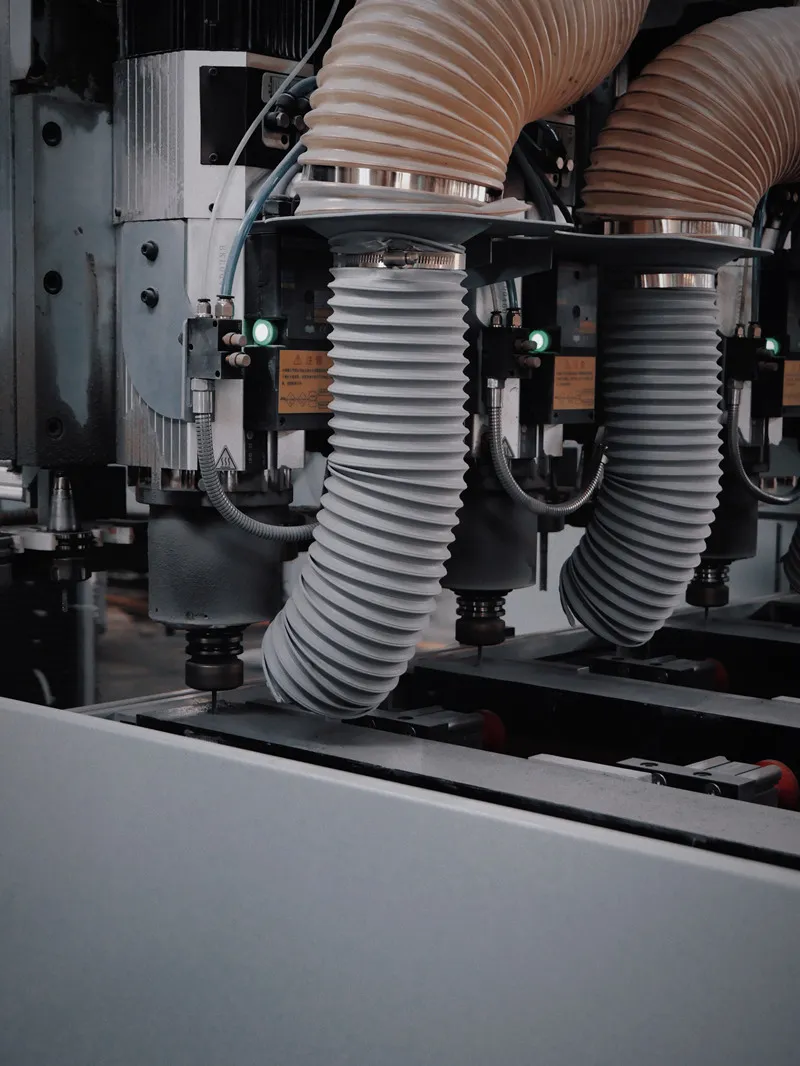

Recently, Nanjing Spare Composites Yizheng Co., Ltd glass fibre pultrusion production line was put into full production, with the world's leading intelligent equipment and the spirit of craftsmanship, to set up a new benchmark in the industry.

Walking into the production base of Spare , the intelligent atmosphere comes to you: imported automatic pultrusion unit running at high speed, from glass fibre wetting, forming to cutting in one go, the tolerance is controlled to about 0.1 mm; closed constant temperature workshop with Internet of Things monitoring system, real-time adjustment of temperature, pressure and other key parameters, to ensure that the product performance is stable as one. According to reports, the production line single-shift production capacity than the traditional equipment to enhance 40%, the annual production capacity exceeded 8,000 tonnes, the core indicators of the domestic first-class level.

The company's more than 100 skilled workers have been in the industry for more than 10 years on average, not only skilled control of intelligent equipment, but also inherited the "millimetre level of truth" of the spirit of craftsmanship. The double guarantee of "intelligent + handmade" makes the pass rate of Spare's products always maintain more than 99.8%.

At present, Spare glass fibre pultruded products have been widely used in new energy, rail transit and other fields, and has reached cooperation with many industry leaders.

As "Spare people", we will continue to empower production with advanced equipment, polish quality with craftsmanship, and inject "Spare power" into industrial chain upgrading.