FRP Composites Empower Electric Vehicle Safety Upgrades, Battery Pack Side Panel Applications Emerge as Industry Focus

2025-09-24

With the accelerated development of the new energy vehicle industry, power battery safety and light-weighting have become core R&D directions for the sector. Recently, FRP (fibre-reinforced composite materials) has achieved large-scale application in electric vehicle battery pack side panels due to its multi-dimensional performance advantages. This provides critical support for power battery system safety protection and overall vehicle energy efficiency enhancement, attracting widespread industry attention.

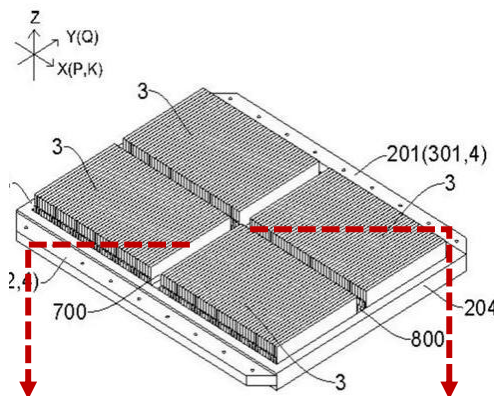

As a core structural component within the battery pack, the FRP composite side panel fulfills multiple critical functions: it not only precisely separates battery modules to ensure internal structural order, but also provides support, thermal insulation, heat dissipation, and cable management. Furthermore, its superior insulation properties resolve the insulation challenges inherent in traditional aluminium profile side panels. Industry test data indicates that FRP materials are one-third lighter than aluminium profiles, effectively reducing the overall weight of the battery pack and thereby enhancing the driving range of electric vehicles. Their insulation resistance far exceeds that of metallic materials, mitigating the risk of leakage at source. Coupled with high resistance to electrical breakdown, they significantly reduce safety hazards in scenarios involving accidental battery leakage.

In terms of adaptability to extreme operating conditions, FRP composites demonstrate equally outstanding performance. This material possesses a high heat deflection temperature, maintaining dimensional stability even in high-temperature environments to prevent structural deformation from compromising battery performance. Through bespoke formulation design, it readily achieves V0-grade flame retardancy requirements, establishing a robust fire barrier for battery packs. Moreover, FRP materials offer exceptional design flexibility, supporting one-piece moulding processes to fabricate complex cross-sectional shapes. This capability perfectly accommodates the customized design requirements of battery packs for different vehicle models, providing new avenues for cost reduction and efficiency gains within the new energy vehicle supply chain.