- Custom Pultrusion Shapes

- FRP Standard Profile

- Vehicle Composite Profiles

- FRP Bridge Components

- FRP Ladder Rail Profiles

- FRP Tool Handles

- FRP Epoxy Pultruded Profiles

- Fiber-Reinforced Connectors

- FRP Covers

- Composite Cooling Tower

- FRP Decking Solutions

- FRP Grating

- Fiberglass Handrail and Fencing

- Fiberglass Windows and Doors Profiles

- Structural Reinforcements and Profiles

- Composite Frames for Solar Panels

- FRP Cable Tray

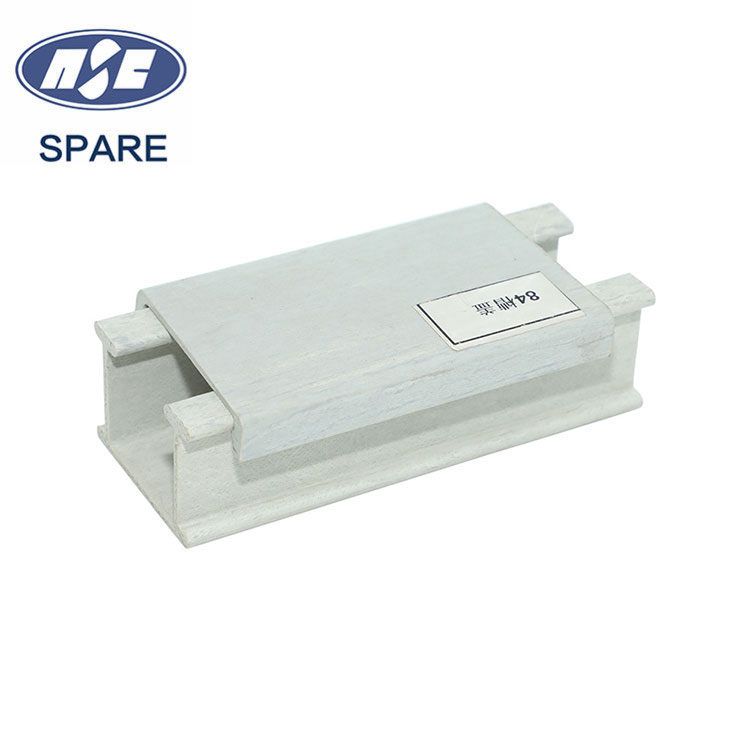

FRP Toothed Tube

FRP Toothed Tube is a high-performance composite material tube that incorporates a specific toothed shape on its inner and outer surfaces to enhance structural rigidity and connection strength. This material combines lightweight, high strength, and corrosion resistance, making it suitable for use in automation machinery, automotive manufacturing, and construction engineering among other fields.

Send Inquiry

Application

Automated machinery

Precision Positioning Devices:FRP Toothed Tube's teeth are designed to mesh precisely with gears or other toothed fittings, ensuring that components in the drive train can be positioned with high precision. This is critical for automated equipment that requires high precision operations, such as CNC machine tools or assembly robots.

Drive shafts:In drive shaft applications, the toothed outer surface enhances friction, prevents slipping and ensures efficient power transmission. They are particularly suitable for heavy load and high torque scenarios, such as large conveyors or drive systems in automated production lines.

Automotive manufacturing

High-performance connectors:The toothed structure of the FRP Toothed Tube can be used as a connector between the body and chassis, providing a stronger connection by engaging the teeth and increasing the overall rigidity and safety of the vehicle. It is suitable for parts that require high strength and stability, such as suspension systems and crash beams.

Engine Mounts:FRP Toothed Tube is used in engine mounts. The toothed design effectively disperses stress, reduces vibration and noise, and improves ride comfort.

Construction

Modular building components:FRP Toothed Tube's toothed design allows it to easily engage with other modular components for quick erection and dismantling, making it suitable for temporary buildings, exhibition halls and emergency rescue facilities.

Reinforcement and connectors:In reinforcement works for bridges or high-rise buildings, the toothed outer surface of FRP Toothed Tube provides higher friction and joint strength, helping to improve the overall stability and seismic performance of the structure.

Specifications

Material

High-strength glass fibers and high-quality resin

Dimensions

Customizable to different lengths and diameters according to customer needs

Color

Standard color is gray, other colors can be customized to fit different application environments

Standards

Complies with international quality and safety standards

Understanding the FRP Pultrusion Process

We are manufactures, engineers, designers and fabricators.

Benefits of FRP

Framework stability

Superior corrosion resistance

lightweight

Easy to install

High Strength

customisable

Durability

Non-Conductive

Non-Magnetic

Thermal Stability

Low Maintenance Costs

Low Thermal Conductivity

Qualification Certificate