- Custom Pultrusion Shapes

- FRP Standard Profile

- Vehicle Composite Profiles

- FRP Bridge Components

- FRP Ladder Rail Profiles

- FRP Tool Handles

- FRP Epoxy Pultruded Profiles

- Fiber-Reinforced Connectors

- FRP Covers

- Composite Cooling Tower

- FRP Decking Solutions

- FRP Grating

- Fiberglass Handrail and Fencing

- Fiberglass Windows and Doors Profiles

- Structural Reinforcements and Profiles

- Composite Frames for Solar Panels

- FRP Cable Tray

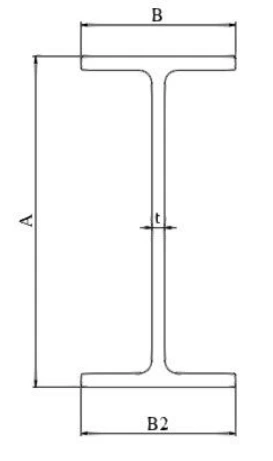

FRP Light Grey I-Beams

FRP light grey I-beams are high-performance structural profiles designed to deliver exceptional strength, durability, and corrosion resistance for a wide range of industrial, commercial, and civil engineering applications. As a modern alternative to traditional steel or aluminum beams, FRP I-beams not only offer a longer service life but also provide significant advantages in installation, maintenance, and overall cost-effectiveness.

Send Inquiry

Product Specification

| Schematic diagram | No. | A | B/B2 | t | ID | |||

|

1 | 25 | 30/30 | 3 | I-0006 | |||

| 2 | 25 | 15 | 4 | I-0950 | ||||

| 3 | 25.4 | 15/15 | 4 | I-0002 | ||||

| 4 | 38 | 15/15 | 4 | I-0001 | ||||

| 5 | 40 | 30/30 | 3 | I-0007 | ||||

| 6 | 40 | 30/30 | 2 | I-0013 | ||||

| 7 | 51 | 18/18 | 5 | I-0005 | ||||

| 8 | 58 | 30/30 | 3 | I-0014 | ||||

| 9 | 65 | 30/30 | 3 | I-0017 | ||||

| 10 | 80 | 60/60 | 3.3/4 | I-0617 | ||||

| 11 | 102 | 51/51 | 6.4 | I-0015 | ||||

| 12 | 103 | 100/60 | 6.35 | I-0009 | ||||

| 13 | 110 | 15 | 5/7 | I-0729 | ||||

| 14 | 110 | 90/100 | 6.5 | I-0891 | ||||

| 15 | 116.5 | 80/80 | 5 | I-0567 | ||||

| 16 | 120 | 70/70 | 8 | I-0011 | ||||

| 17 | 120 | 120/120 | 8 | I-0329 | ||||

| 18 | 126 | 90 | 6.5/7 | I-0853 | ||||

| 19 | 130 | 105 | 6 | I-0986 | ||||

| 20 | 139.7 | 63.5 | 6.35 | I-0722 | ||||

Core Materials and Manufacturing Processes

Core Materials: Mostly composite materials such as glass fiber-reinforced resin, consisting of a resin matrix and a glass fiber reinforcement phase. Light grey is a common color option, offering both light weight and high strength.

Manufacturing Processes: It falls under rapid prototyping (RP) technology. First, a CAD model is created and sliced into layers. Then, resin is selectively cured by laser or materials are sintered, and the product is formed by layer-by-layer superposition. Alternatively, processes like pultrusion and injection molding are also used for production.

Dual Value of the Light Grey Appearance

The light grey color of FRP I-beams not only enhances aesthetics but also provides practical benefits. This neutral tone blends seamlessly with modern architectural and industrial designs, while also offering excellent resistance to fading, UV radiation, and weathering. Unlike metal beams, FRP beams do not rust, corrode, or require frequent repainting. Even after long-term exposure to sunlight, rain, and chemicals, their surface remains clean and intact, ensuring long-term stability in both appearance and performance.

Wide Range of Application Scenarios

Thanks to their core advantages of light weight, high strength, and corrosion resistance, FRP light grey I-beams are used across multiple key industries. In the construction sector, they are often used for roof support in large venues and as keels for glass curtain walls, with their light grey appearance naturally integrating into modern architectural aesthetics. In municipal engineering, they serve as crossbeams for sewage treatment tank covers and load-bearing structures for bridge inspection walkways, capable of withstanding corrosion from acidic and alkaline media. In the new energy industry, they are used for platform support inside wind turbine towers and as crossbeams for photovoltaic brackets, with their lightweight feature reducing installation costs. Additionally, in humid or corrosive environments such as marine engineering and chemical workshops, their performance far surpasses that of traditional metal I-beams, making them the preferred alternative to steel and aluminum materials.

Advantages of Easy Installation

Another significant advantage of FRP I-beams is their ease of installation. Weighing approximately one-quarter of steel, they can be transported and assembled without the need for heavy lifting equipment. This not only reduces labor costs but also shortens project timelines. Furthermore, FRP beams can be cut, drilled, and machined using standard tools, providing greater flexibility for customized designs and on-site adjustments.

Safety and Sustainability Features

Safety and sustainability are also core characteristics of FRP materials. FRP is non-corrosive and non-sparking, creating a safer working environment, especially in hazardous or flammable areas. In the long run, the durability of FRP beams significantly reduces the need for replacement and maintenance, thereby minimizing material waste and resource consumption, and demonstrating good environmental friendliness.

Conclusion

In summary, FRP light grey I-beams perfectly combine strength, practicality, and aesthetics. They offer excellent structural performance, outstanding resistance to environmental damage, and long-term stable color retention. Whether used in construction, infrastructure, chemical plants, or marine environments, their reliability and efficiency exceed expectations. With their high strength-to-weight ratio, easy installation, and maintenance-free nature, FRP light grey I-beams have become an intelligent, sustainable, and forward-looking solution to meet the needs of modern engineering.

Understanding the FRP Pultrusion Process

We are manufactures, engineers, designers and fabricators.

Benefits of FRP

Framework stability

Superior corrosion resistance

lightweight

Easy to install

High Strength

customisable

Durability

Non-Conductive

Non-Magnetic

Thermal Stability

Low Maintenance Costs

Low Thermal Conductivity

Qualification Certificate