- Custom Pultrusion Shapes

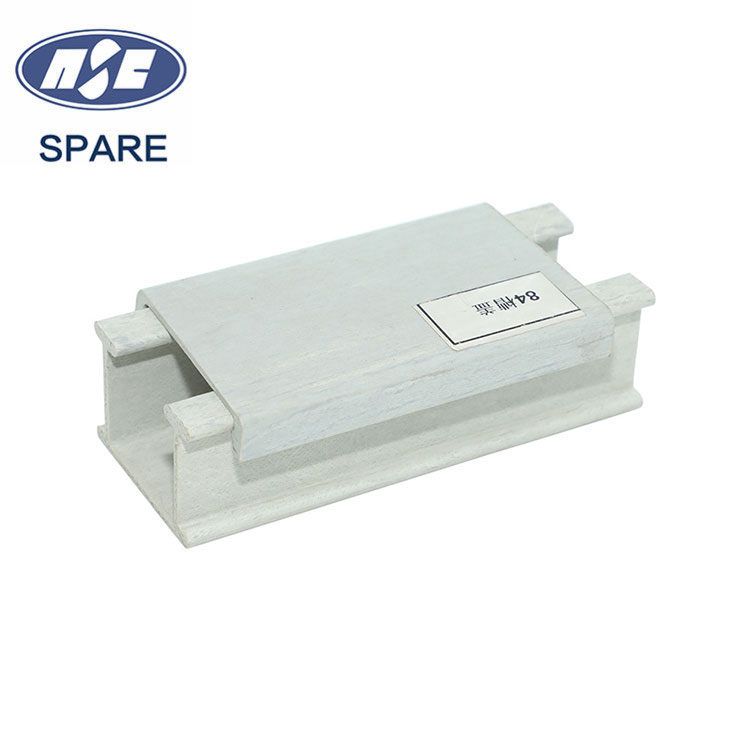

- FRP Standard Profile

- Vehicle Composite Profiles

- FRP Bridge Components

- FRP Ladder Rail Profiles

- FRP Tool Handles

- FRP Epoxy Pultruded Profiles

- Fiber-Reinforced Connectors

- FRP Covers

- Composite Cooling Tower

- FRP Decking Solutions

- FRP Grating

- Fiberglass Handrail and Fencing

- Fiberglass Windows and Doors Profiles

- Structural Reinforcements and Profiles

- Composite Frames for Solar Panels

- FRP Cable Tray

Fiberglass Rebar

Fiberglass rebar complies with the JGT406-2013 standard, and its core advantage lies in the combination of performance and practicality: its tensile strength is more than twice that of traditional steel bars of the same specification, it is light in weight, resistant to acid, alkali and chloride ion corrosion, and has a longer service life in harsh environments.

Send Inquiry

Fiberglass rebar is a new type of structural material made from high-strength glass fibers and synthetic resins through a composite process. Its full-thread rod design is suitable for various engineering needs. Its core advantages are remarkable: the tensile strength is more than twice that of traditional steel bars of the same specification, with a density of only 1.5-1.9g/cm³ and a weight merely 1/4 of that of steel, which significantly reduces the cost of construction and transportation.

Product Advantages

Fiberglass rebar has outstanding characteristics: it is resistant to acid, alkali and chloride ion corrosion, and has a much longer service life than traditional steel bars in harsh environments such as coastal areas and chemical industries; its thermal expansion coefficient is closer to that of cement, and it has strong bonding force with concrete, which improves the structural integrity. In addition, it is non-magnetic and insulating, easy to cut (can be directly cut with a cutter head) and does not require welding, making it suitable for shield machine construction scenarios.

In accordance with the JGT406-2013 standard, its diameter ranges from 3mm to 40mm, with a tensile strength of ≥450MPa, an elastic modulus of 30-41GPa, and an alkali resistance of no less than 75%. It is widely used in fields such as subway diaphragm walls, bridge deck paving, marine engineering and historical building restoration, and is a preferred material for replacing traditional steel bars.

Applications

Fiberglass rebar is suitable for scenarios such as shield machine construction and is widely used in fields including subway diaphragm walls, bridge deck paving, marine engineering, and historical building restoration. It is an efficient and preferred material to replace traditional steel bars.

●Civil Engineering: It is applicable to bridge structures, tunnel support systems, highway pavement reinforcement, and retaining wall load-bearing components.

●Marine Construction: It can be used in port terminal structures, pier load-bearing parts, and seawall anti-corrosion projects that are in long-term contact with saltwater.

●Industrial Facilities: It is suitable for anti-corrosion reinforcement of chemical plant equipment foundations, structural parts of nuclear power plant auxiliary facilities, and load-bearing components of cooling tower structures.l

●Renewable Energy: It can be applied to the foundation reinforcement of ground-mounted solar farm bracket systems and the base load-bearing structures of onshore/offshore wind turbines.

Understanding the FRP Pultrusion Process

We are manufactures, engineers, designers and fabricators.

Benefits of FRP

Framework stability

Superior corrosion resistance

lightweight

Easy to install

High Strength

customisable

Durability

Non-Conductive

Non-Magnetic

Thermal Stability

Low Maintenance Costs

Low Thermal Conductivity

Qualification Certificate