News

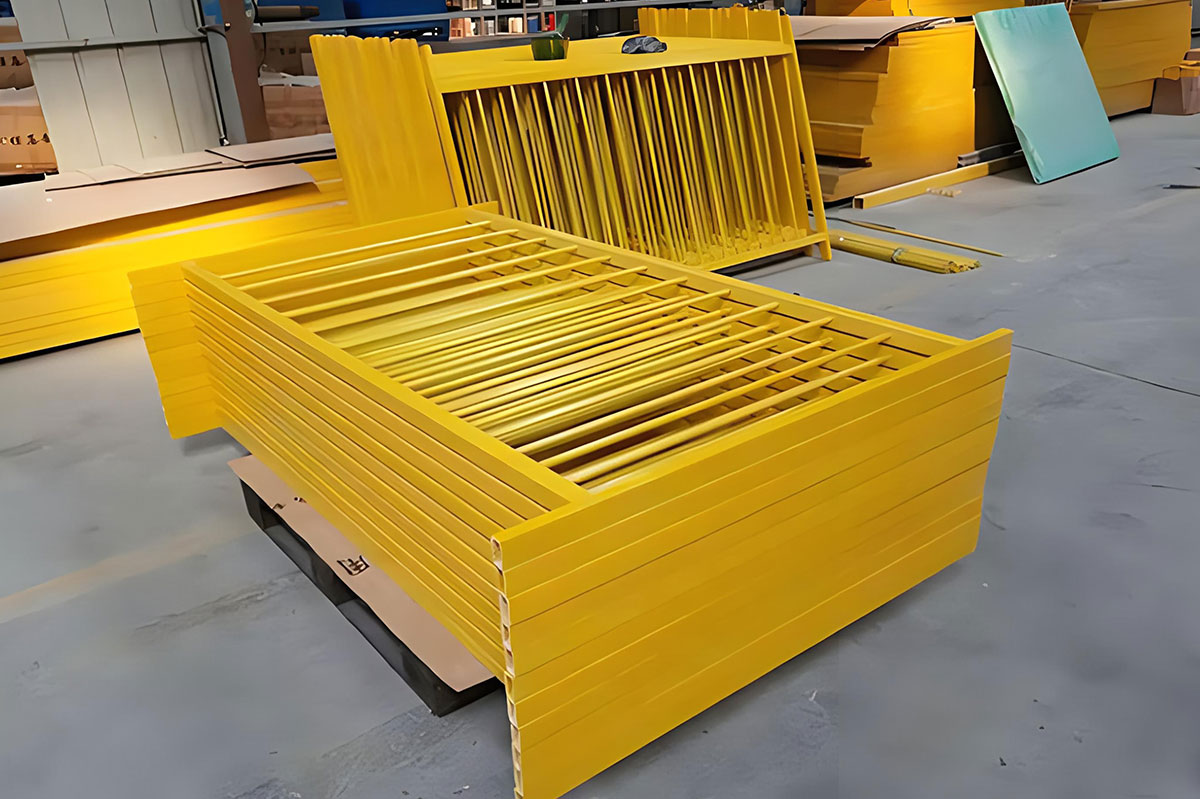

Advantages of FRP Rectangle Tubes

FRP rectangle tubes are made from materials such as epoxy resin and high molecular weight unsaturated polyester resin, which effectively resist acid and alkali corrosion in practical applications. They are also suitable for transporting some corrosive chemical reagents and liquids.

Read MoreAdvantages and Applications of FRP in the New Energy Industry

The new energy industry is rapidly emerging, and within this context, the utilization of FRP (Fiber Reinforced Plastics) has gained increasing attention. To delve deeper into its significance, this article outlines the key advantages of FRP and its detailed applications in the new energy sector.

Read MoreThe Connecting Bridge Between the Department of New and Old Civil Engineering at Tsinghua University

The corridor bridge at Tsinghua University Civil Engineering Department uses GFRP panels as permanent formwork for its deck. These panels are chosen for their light weight, ease of construction, and durability. They are secured to the secondary girders with bolts and can be manually adjusted on-site......

Read MoreShenyang Vanke FRP Floating Window Project

Changchun Parkview's FRP floating windows feature Spare's pre-processed hollow web panels, allowing for easy installation with factory bolts. This saves costs and labor while offering customizable dimensions for diverse settings. The eco-friendly manufacturing process replaces noisy masonry methods,......

Read MoreShenyang Vanke Connector Project

Spare's sandwich insulation wall FRP connector is pivotal for linking concrete slabs on insulation boards, resisting lifting and shear forces. Comprising FRP connecting plates and ABS engineering plastic collars, it ensures secure connections and accurate positioning during concrete pouring. With ex......

Read MoreRoof Deck Applications

The roofing material used is FRP deck supplied by Spare, which has a light weight and a thickness of 40cm. The width of the FRP deck is 500cm and its length can be adjusted according to the design requirements, with a maximum length of 3000cm. The FRP deck serves as both the top and bottom layers of......

Read More