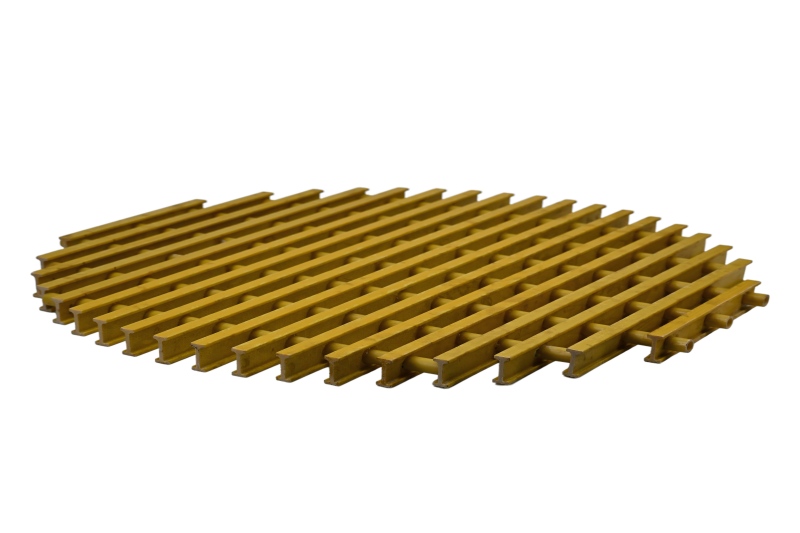

Spare FRP Pultruded Grating – High-Performance Composite Material Solutions

2025-09-05

Product Characteristics

Spare FRP Pultruded Grating is manufactured through the pultrusion process using fibreglass-reinforced plastic (FRP). It offers the dual advantages of high strength and lightweight construction, weighing approximately one-third that of steel while achieving comparable strength. This facilitates transportation and installation while reducing support structure costs. Surface patterns or textured finishes can be designed, providing excellent slip resistance in wet conditions to ensure safety. Insulating and flame-retardant, they are non-conductive and non-magnetic, achieving a B1 flame-retardant rating suitable for specialized electrical environments. Maintenance-free and durable, they resist corrosion and decay, with a service life exceeding 20 years. The open grid structure facilitates drainage, ventilation, and daylight penetration, while minimizing water and debris accumulation.

Applications

Widely applicable across multiple sectors: - Industrial settings: suitable for chemical plant platforms, wastewater treatment plant walkways, electroplating workshop flooring, and oil rig gangways; In municipal engineering, suitable for pedestrian footbridges, drainage channel covers, and tree pit covers; In transport and energy sectors, applicable for substation inspection walkways, wind turbine platforms, and ship decks; In commercial facilities, suitable for car wash gratings, food processing plant workbenches, and anti-slip layers in underground car parks.

Customization Services

As a renowned Chinese FRP manufacturer and trader, Spare has specialized in FRP pultrusion and compression moulding products for many years, backed by a professional R&D team and comprehensive production systems. We support customization of FRP pultruded gratings and various FRP products, flexibly adjusting parameters such as shape, dimensions, and spacing according to your project requirements. Surface treatment processes can also be tailored to meet specific demands across different scenarios, delivering bespoke FRP composite solutions.