SPARE FRP rectangles: excellent performance, hot sales at home and abroad

2025-09-02

With its outstanding performance and reliable quality, FRP rectangular profiles from SPARE have continued to be popular in both domestic and overseas markets, and have won wide recognition and praise.

FRP, or Fibre Reinforced Plastic, consists of a resin matrix reinforced by fibres (usually glass fibres). SPARE's FRP rectangles are manufactured using an advanced pultrusion moulding process and possess a number of key characteristics. With an excellent strength-to-weight ratio, it is durable and much lighter than traditional materials such as steel and aluminium, reducing overall weight while ensuring structural strength, an advantage that is particularly prominent in weight-sensitive areas such as aerospace and vehicle manufacturing. At the same time, it has excellent corrosion resistance, no fear of moisture, chemicals and harsh environments, and will not rust, suitable for marine engineering, chemical plants and other corrosion-prone scenarios.

The SPARE 800*300 large rectangular pipe used in the connecting corridor of Qingdao “JinYuLanWan” project still maintains good performance under the complicated environment.

In addition, FRP rectangles are fatigue-resistant and can withstand repetitive cyclic loads; have high design flexibility and can be customised according to specific requirements; have good electrical insulation and are commonly used in electrical enclosures; have good thermal insulation, which helps to improve energy efficiency; are non-magnetic, which plays an important role in the fields of medical equipment and electronic products; and are weather-resistant, which can be subjected to ultraviolet radiation, humidity and temperature changes in the long term.

In practical applications, SPARE FRP rectangular material performs well. In the field of construction and infrastructure, it can be used as structural frames and support parts to provide solid support for buildings; in the chemical energy industry, its corrosion-resistant characteristics make it an ideal material for transport pipelines, reactors and other equipment; in sewage treatment, it can resist sewage corrosion and ensure the long-term stable operation of the facilities; in the field of road traffic, it is used in the construction of pedestrian bridges, guardrails and other construction; in marine engineering, it can meet the needs of offshore platforms, ships and other facilities; in electric power engineering, it can be used as a material to meet the requirements of power plants and other facilities. In marine engineering, to meet the needs of offshore platforms, ships and other facilities; power engineering, as an insulating component to ensure the safety of power transmission; agricultural farming can build greenhouses, breeding fences and so on. Like the FRP structure of Spain's footbridge, as well as the hospital using SPARE's customised lightweight double-hole structure profiles to build a platform for stopping the plane, have fully demonstrated the advantages of the product.

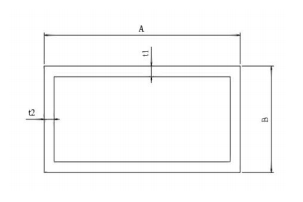

It is worth mentioning that SPARE can customise FRP rectangular profiles according to customers' needs in terms of shape, size, chemical or physical properties, and provide services such as cutting, drilling, CNC machining and bonding. With strong customisation ability and high quality products, SPARE's FRP rectangular profiles are not only sold well in China, but also exported to the US, EU, Middle East, Japan, Southeast Asia and other countries and regions, and are widely used in many industries around the world, providing reliable solutions for many projects.