Sandwich panels: the construction industry's thermal insulation magic weapon

2025-08-13

Recently, a new type of building material - FRP sandwich panels with excellent thermal insulation performance, in the construction industry has attracted widespread attention, known as the industry as "thermal insulation magic weapon".

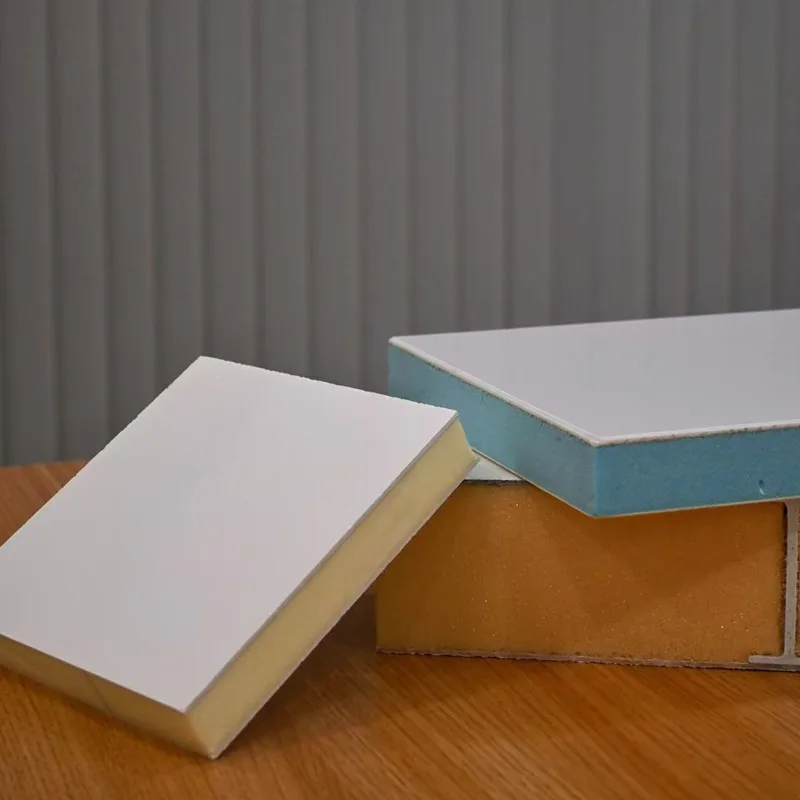

This sandwich panel structure is unique, by two layers of FRP (fibre reinforced composite materials) as a panel, sandwiched between a layer of high-efficiency thermal insulation foam core material, forming a "sandwich" type composite structure. FRP material is lightweight, high strength, corrosion-resistant, can provide a solid support for the plate; the foam layer in the middle of the excellent thermal insulation and heat preservation performance, effectively blocking heat transfer, significantly improving the heat preservation performance. The foam layer in the middle has excellent thermal insulation properties, effectively blocking heat transfer and significantly improving the energy efficiency of the building.

Compared with traditional building materials, FRP sandwich panels have significant advantages. It weighs only 1/5 of traditional steel, is easy to install, and can significantly shorten the construction period; at the same time, its good anti-aging and waterproof performance makes it suitable for factories, warehouses, movable rooms, and other scenarios. In cold regions of the building project, the use of the sandwich panel building winter heating energy consumption reduced by more than 30%, summer can also reduce the use of air conditioning, the real energy saving and emission reduction.

Industry experts said that the promotion and application of FRP sandwich panels not only meets the development trend of green building, but also provides strong support for the construction industry to reduce costs and increase efficiency. With the continuous maturation of the technology, this "insulation magic weapon" is expected to play an important role in more areas, and promote the construction industry to low-carbon, efficient direction.